Sorting of household packaging in France

French people have had (at least) two bins for many years now: one for household waste, the other for sorting packaging and paper. This organisation is due to the implementation of selective collection in the 1990s. But what happens to this packaging once it has been disposed of in the sorting bin? It is sorted! The objective: to direct it to the right recycling stream. But how is this achieved?

Stage one: sorting

The products that we buy as citizens and consumers are packaged to preserve and protect them and to provide consumer information: once they have been consumed, the packaging should be disposed of in the sorting bin.

In France, it is possible to sort ALL types of packaging nowadays, including plastic packaging. For paper, it’s simple: all paper can be sorted (newspapers, magazines, letters, envelopes, exercise books, etc.).

This is good news, since these sorting habits are crucial to give a new life to as much packaging and paper as possible.

Stage two: collection of sorted packaging and paper

Once your packaging and paper have been sorted, the sorting bins and containers at sorting points are collected by collection workers, also called waste or rubbish collectors. During this collection stage, all this packaging and paper is taken to the nearest sorting centre. Glass packaging is sent to processing centres where it is cleaned and crushed before being transformed into new glass packaging.

Where? Packaging waste is collected from all sorting points.

How? It is mostly collected by refuse trucks that come and collect the sorted waste. Sometimes, these are camions biflux, collecting both household waste and recycling waste at the same time, while keeping them separated in two compartments.

Who? Local authorities, which bring together several municipalities within a territory, are responsible for waste management, and they sometimes call on private contractors.

Stage three: sorting centre

There are over 120 sorting centres in mainland France, managed by waste treatment unions and funded by local authorities (several local authorities can join together within the same union to manage their waste) in collaboration with private contractors.

All of these sorting centres operate in a similar way, but when we look more closely we can see differences from one sorting centre to another (whether in terms of the sequence of machines, the path of the packaging, or the material recirculation systems). This is due to the specific characteristics of each site (location and consumption profile of the citizens assigned to each sorting centre, quantity of packaging handled, available space on the industrial site, age of the machines, etc.). Nevertheless, all these sorting centres share the same sorting objectives.

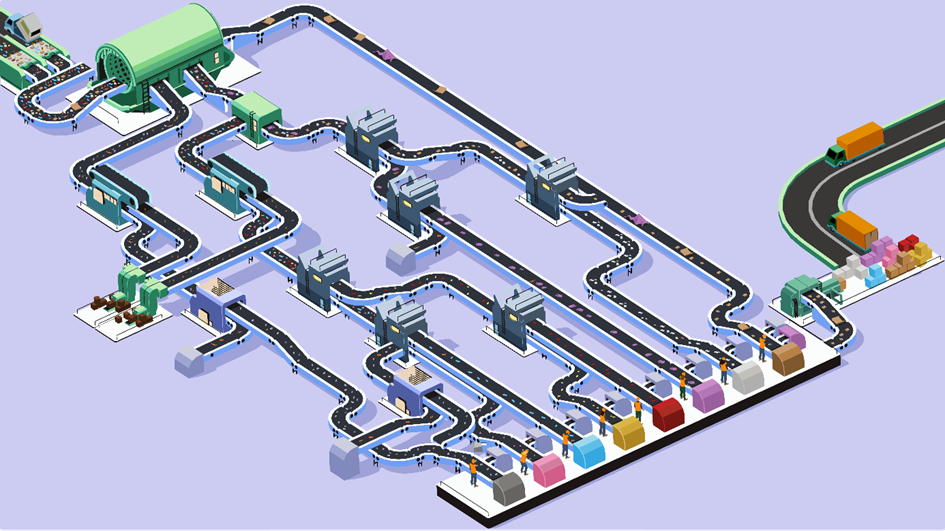

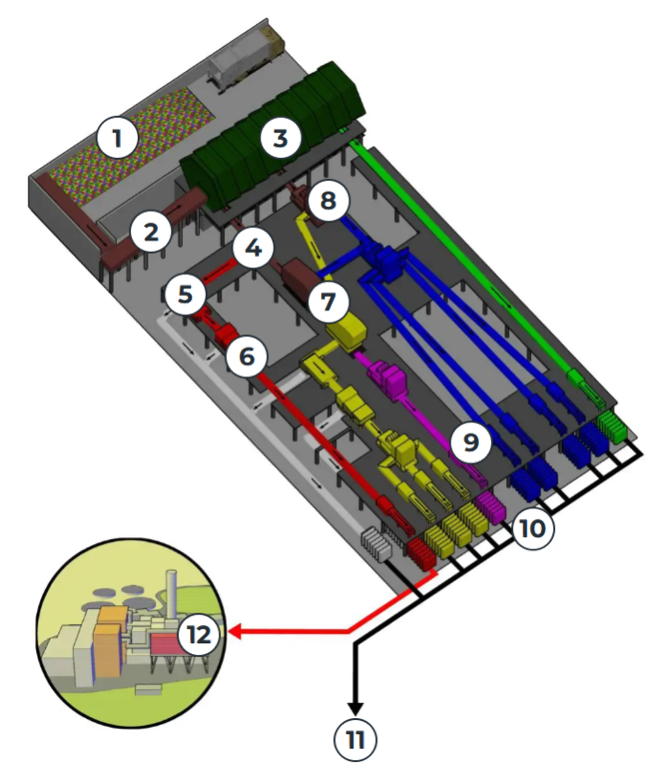

To better understand how a sorting centre works, let’s take a look at this diagram:

Collection trucks bring packaging and paper to sorting centres – industrial sites – which, thanks to numerous machines and sorting agents at the end of the line, will separate all the collected packaging and paper by material.

Unloading

1 – Upon arrival and departure from the sorting centre, trucks are weighed on weighbridges to determine the weight of the received waste. They unload the packaging and paper in the unloading area.

Feed hopper

2 – The waste stored in the unloading area is transported by a machine into the feed hopper. This hopper consists of a conveyor belt that regulates the flow to the sorting line, preventing too much waste from arriving at once.

Separation by size

3 – The trommel screen is a rotating drum with holes of various diameters that sorts waste by size:

- The smallest waste items pass through to the fine screen (<200 mm);

- Medium-sized waste items (bottles, cans, etc.) continue along the sorting line;

- The largest waste items (cardboard, paper, etc.) go directly to the manual sorting cabin.

4 – After leaving the trommel screen, the smallest waste items (<200 mm) pass through the fine screen. This machine further separates the waste by size: generally, waste items that are larger than 50 mm continue along the sorting line, whereas waste items that are smaller than 50 mm are sent to sorting rejects.

Separation of magnetic metals

5 – An overband is a machine equipped with a large magnet that captures ferrous objects (such as cans, aerosols, etc.) using magnetic attraction.

There are usually two of them in a sorting centre: one on the reject line (red) and the other on the hollow containers line (yellow). In both cases, this system is used for recovering steel waste and transporting it directly to the storage compartment dedicated to this material.

Separation of non-magnetic metals

6 – An Eddy current machine is used for recovering aluminium packaging by means of a powerful magnetic field.

Just like the overband machines, there are generally two Eddy current machines in each sorting centre: one on the reject line (red) and the other on the hollow containers line (yellow). They are used for recovering aluminium waste and transporting it directly to the storage compartment dedicated to this material.

Separation by shape

7 – During its journey through the sorting centre, the waste passes through several ballistic separators which help to separate hollow containers (yellow), such as plastic bottles, cartons, cans, etc., from flat materials (blue), such as newspapers, magazines and small cardboard items. These separators consist of an inclined, vibrating conveyor belt that moves in a circular motion: the heavier hollow containers bounce and head downwards, while the flat materials settle on the belt and are carried upwards.

Separation by material

8 – During its journey through the sorting centre, the waste passes through several optical sorters that can sort it more precisely according to its composite materials.

The waste is identified using a beam of light (a scanner that identifies colours) and an infrared sensor (which detects materials). Once identified, the different types of waste are directed by an air stream to the appropriate conveyor belt.

A conveyor belt regularly feeds the material to be sorted (1). On the belt, the material is detected by NIR and/or VIS spectrometer sensors (2). An ejection ramp equipped with solenoid valves is located at the end of the conveyor. When the sensors detect items to be ejected, the solenoid valves open at a precise moment. The selected items are sorted by jets of air. The sorted material is separated into two or three fractions (3).

Manual sorting

9 – After being separated by optical sorters, the waste is transported to the sorting table according to the materials that it is made of.

The sorting centre workers then sort the waste manually to finish sorting by material and eliminate any remaining errors.

Storage and shipping

10 – All the materials separated through the sorting centre process are temporarily stored in separate compartments.

11 – Each material is then transported one by one on a conveyor belt to the bale press. This machine compresses the sorted waste into large cubes called “bales”.

This packaging method saves space for storage and for transport to the recycling streams.

After this final stage, the sorted waste is sold to companies known as “buy-up operators“. They recycle the materials to give them a second life.

12 – Sorting rejects are removed throughout the sorting process. They are either redirected to energy recovery units to be incinerated and converted into energy or sent to landfill sites for disposal.

Stage four: recycling plants

These plants accept all materials that have a recycling stream.

Find out about the recycling streams in France (in French)

In recycling plants, packaging and paper go through several mechanical transformation stages, which vary depending on the material, to become raw materials again. They can be shredded, washed, melted, etc. For plastics, “chemical” recycling, for example by pyrolysis, is also being tested.

At the end of these processes, the materials take the form of flakes for plastic, pulp for paper and ingots or blocks for metals.

Stage five: a new life for recycled packaging and paper

Once processed in recycling plants, the materials become secondary raw materials, which can be used for manufacturing new packaging or products.

Stage six: transformation into new packaging or products

After all these stages, the packaging and paper can be reincorporated into new products, packaging or paper, which can be used again.

This circular economy, which enables waste recycling, is essential to reduce the environmental impact of consumption. But it’s not the only solution. The main aim is to reduce the amount of packaging in the first place, particularly through eco-design, to pare it down to the bare minimum or even eliminate it entirely. A second priority is reuse, which involves using the same packaging multiple times for the same purpose.